Make your very own split keyboard

8.7.2025. 6 min read

INTRO

At the very beginning of the year, 12 hours into the New Year, I broke my wrist mountain biking, even after taking the bandage off, using a regular keyboard was painful enough to make me seriously reconsider the way I typed.

Looking at all the split keyboard options quickly made me realise how overpriced everything was, and it was then that I decided to make one of my own. As with anything, the process is actually pretty straightforward once you break it down:

- take it apart

- draw and measure the PCB

- model the PCB and test the fit

- design the keyboard case

ABOUT THE PROCESS

Measuring everything out

Step 1: Take the keyboard apart

Pretty straightforward.

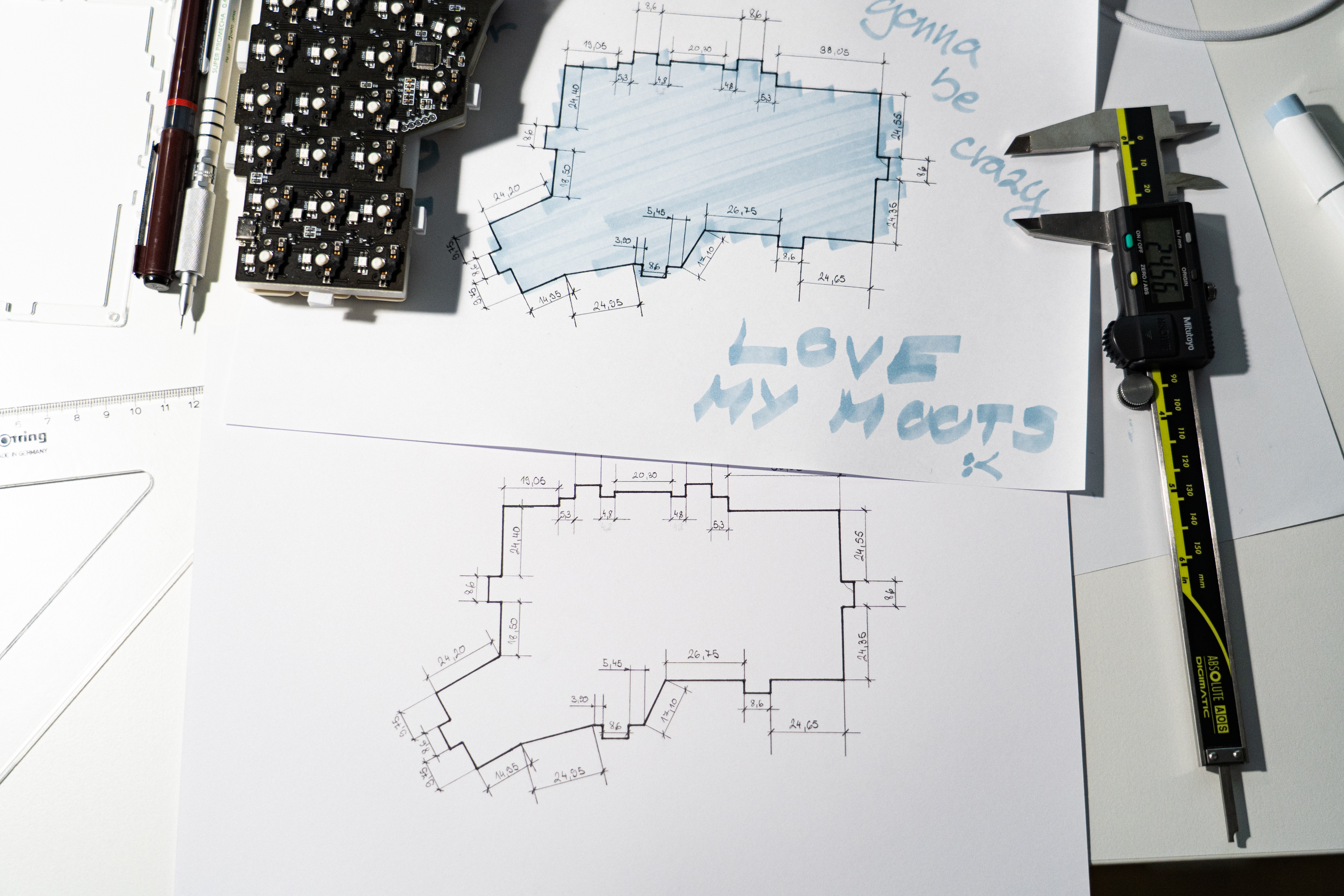

Step 2: Draw and measure everything

Honestly, this is my favourite part of my projects in general. I really like drawing, I really like sketching, and using cool calipers to measure everything. I think sketching things out on paper helps most people, but paper’s kind of a dying breed these days. Manually drawing takes way more time than just modeling everything directly in CAD and measuring as I go, but I find myself enjoying it quite a lot so, I’ll keep it analog.

Hand-drawn technical drawing

Step 3: CADin’ everything up

The next step, though, is easily the most annoying. It takes a lot of iteration to get a perfect fit. You're never going to get it exact, but you try to get as close as possible, and that takes time, considering printing times. The worst part is once you finally get to your desired tolerances, everything fits, and only then you realise that the chinese pcb is off on the left half of the keyboard.

Additional pieces for an airtight fit

Step 4: Designing the case

Once you have the fitment for the keyboard, everything else is easy. You can do whatever you want, however you want. I honestly have not spent too much time dwelling on the design and just did whatever was the fastest. In retrospect, I could have done a better job, but there’s always version 2.

FILES (download .stl || .f3d)

Follow this link to: View Project on GitHub

TAKEAWAY FROM THIS PROJECT

The most important thing here is that nothing is stopping you from building your own thing. If you can imagine it, you can make it. You don’t need to sell it or show it off. You can build things just for you. Today, 3D printers are cheaper than ever. Whether you’re using a €150 printer or a Bambu one, what matters is to play around with your thoughts: sketch them, model this, print that, build it. Make something you’re proud of and make it yours.

It's up to you, anon